Glass Recycling Plant | |||||||||

|

| ||||||||

What is "Foamed Glass" |

|

From natural minerals to glass ---- Reduction from glass to nature

Inorganic materials with many characteristics |

|

|

| The raw material of glass is quartz, sodium carbonate, limestone and other natural minerals. It was used for various purposes such as a large glass bottle, a small multicolored bottle, a window glass of a building, and so on. And someday it will be used ... |

| We changed the shape of the used glass to a new shape called lightweight aggregate. Various effects have been confirmed in various fields, and it is attracting attention as an eco material without load on the environment. "Foamed Glass" will be useful in the future, and in harmony with the natural world, it will fulfill its role well. At the glass recycling plant, we are producing "Foamed Glass" such as" Formed-G®", "Super-Sol®" and "Porous-Alpha®". |

Physical Properties of the "Foamed Glass (Super-Sol®)" |

Chemical conposition | ||||||||||||||||||||||||||||||

|

| |||||||||||||||||||||||||||||

Design constant |

| Dry density iton/m3 j | Design constant | Rolling pressure number of 30 cm thicker | |||

|---|---|---|---|---|---|

| Wet density iton/m3 j | Angle of internal friction (°) | Permissible support force ikN/m2 j | 10 ton wetland bulldozer (times / layer) | 1 ton class vibration roller (times / layer) | |

| 0.25 | 0.40 | 25 | 39 | 0 | 0 |

| 0.30 | 0.45 | 30 | 98 | 2 | 4 |

| 0.35 | 0.55 | 37 | 4 | 8 | |

| 0.40 | 0.60 | 176 | 8 | - | |

| Single body | Compacted | ||

|---|---|---|---|

| Dry density (ton/m3) | From 0.4 to 0.5 | Density (ton/m3) | From 0.3 to 0.4 |

| Particle size distribution range (mm) | From 2 to 75 | Triaxial compression strength (Angle of internal friction) | More than 30° |

| Water content ratio (wt%) | 0 | Permeability coefficient of water (cm/s) | From 3 x 100 to 1 x 10-2 |

| Uniaxial compressive strength (kgf/cm2) | From 30 to 40 | ||

| Hazardous substance | No water elution | ||

Characteristics by type |

| Type | Dry specific gravity | Water absorption (wt%) | Characteristic | Uses | ||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L1 | 0.3 - 0.6 | More than 30 |

|

| ||||||||||||||||||||||||||||||

| L2 | 0.4 - 0.5 | Less than 30 |

|

L3 | 0.5 - 1.0 | Less than 10

|

|

L4 | 1.0 - 1.6 | Less than 5

|

|

|

| |||||||||||||||||||||

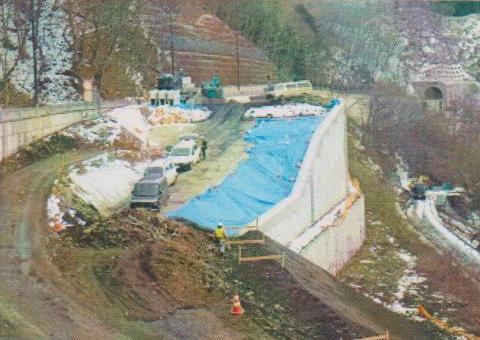

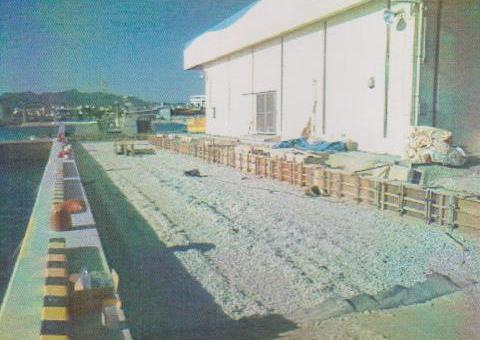

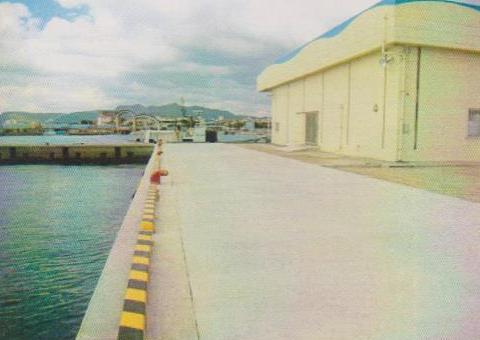

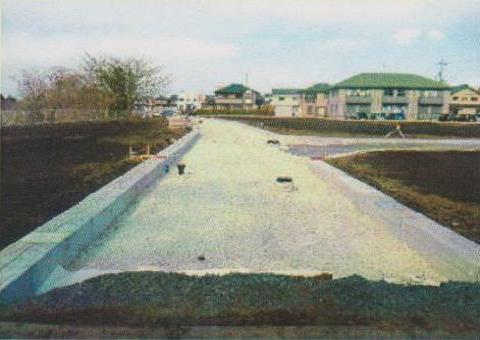

Several examples of civil engineering construction |

| (Source: Glass Foam Business Cooperative) |

|

|

|

Example of Japanese garden using "Hirokawa-Aoishi (light-green stone)" and "Foamed Glass (Foamed-G®)" |

|